Description

Discover The Evolution of Endodontics and Elevate Your Practice with EVO FLEX

EVO FLEX is a cutting-edge rotary NiTi file combining advanced endodontic science with top-tier metallurgy. Featuring a unique bullet penetration guide tip, EVO FLEX enables safe, predictable shaping while minimizing the number of instruments needed.

01 Bullet Guide Tip: Elevating preparation for seamless apical access, avoiding ledging and deviations.

EVO FLEX's Bullet Tip features two strategic angles—one at the tip and another leading into the cutting area—enhancing safety and penetration in complex anatomical pathways.

The SEM of the EVO FLEX penetration guide shows the smooth transition between the tip and the initial working cutting laminas.

02 Variable S Cross-Section: Precise penetration control, enhanced cutting efficiency, and optimized debris removal

The EVO FLEX features a modified S-shaped cross-section that enhances cutting efficiency, penetration control, and centricity, particularly in the apical region. Its transition to an asymmetrical design increases flute space for better debris removal, cutting efficiency, and flexibility.

03 C-Wire Heat Treatment: Optimizing flexibility and enlargement efficiency to minimize the risk of separation

EVO FLEX's C-Wire heat treatment enhances NiTi alloy flexibility, reducing the risk of instrument separation from cyclic fatigue. Unlike purely martensitic alloys, it maintains cutting efficiency while allowing smooth navigation through canal curvatures, achieving a balance between safety, efficiency and fast instrumentation.

Methodology: 90° Curvature/500 RPM

Internal Tests. Data on file.

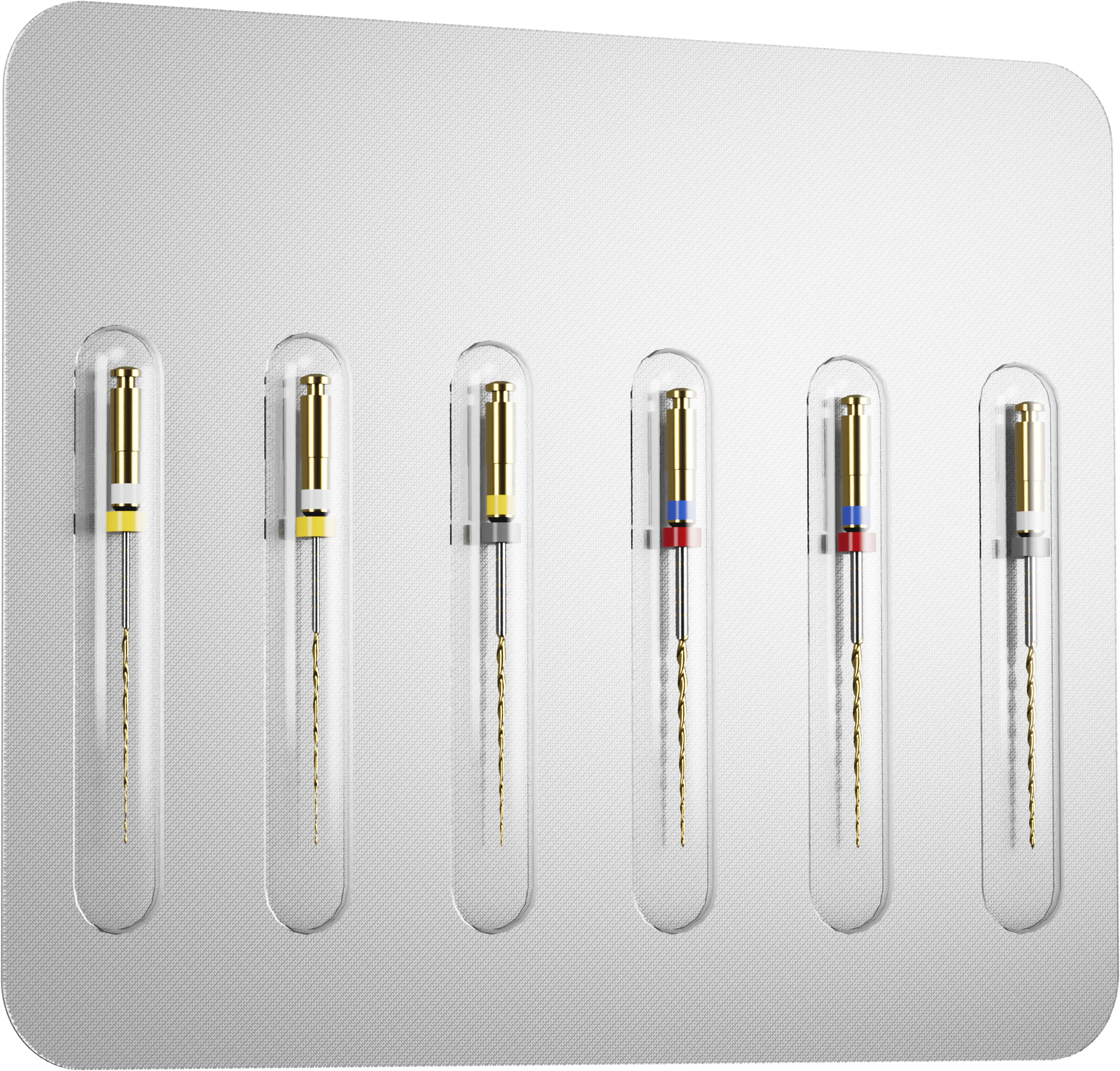

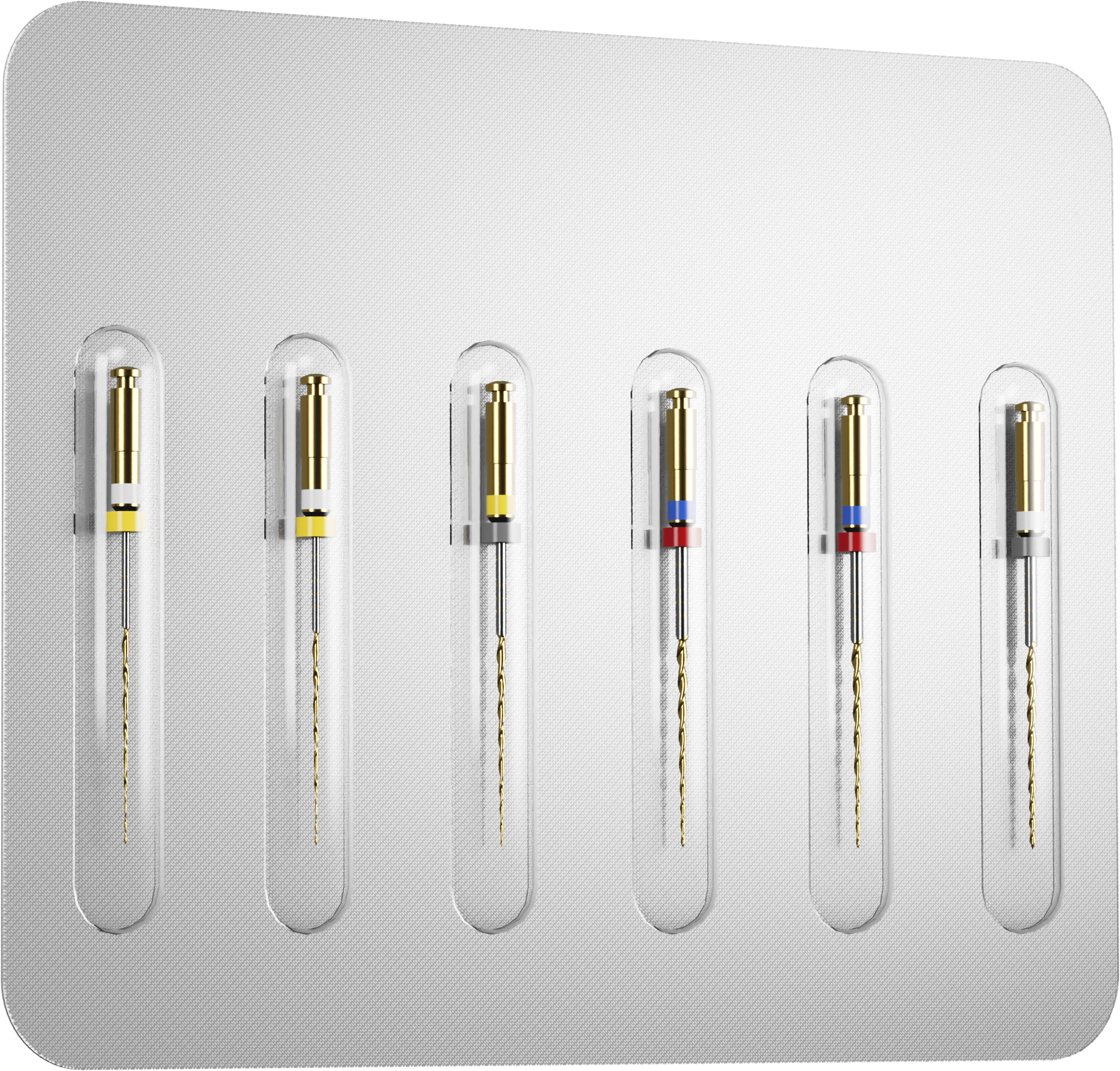

04 Two Files for Most Cases: Easy to Learn and Simplifies the Workflow

EVO FLEX overcomes the limitations of single and multiple file systems by ensuring effective apical enlargement with 2 files only in most of the cases.

Beside the primary shaping file, and to cover most exotic anatomical complexities, EVO FLEX includes two additional accessory files designed for narrow, and large canals.

Establishing working Length, Patency and Glidepath

1. Explore the canal with small hand files (ISO 08 or 10) until estimated working length is reached.

2. Confirm the Working length with an apex locator (e.g., AI-Pex™) and X ray.

3. Establish patency using a hand file ISO 10.

4. Create a mechanical Glidepath using EVO FLEX 14/03 at 500 rpm, torque 1 N/cm, with long strokes of inward and outward motion until reaching the working length.

5. Irrigate and recapitulate.

File Selection and Operational technique

Standard Canals (straight or medium curved canals)

• Fill the canal with irrigant.

• Use EVO FLEX 30/04 at 500 rpm, torque 2.5 N/cm, with a gentle apical movement until resistance is encountered. Then, withdraw the file in circumferential brushing movements on lateral walls.

• Remove the file and clean the flutes.

• Irrigate and confirm patency using K-file #10.

• Reintroduce EVO FLEX 30/04 as described previously; 2 to 3 repetitions are generally needed to reach the working length.

• Proceed with the final irrigation protocol and obturation.

Narrow and curved canals

• After establishing manual and rotary glidepath using K-file # 10 and EVO FLEX 14/03.

• Use EVO FLEX 20/04 at 500 rpm, with a torque of 1.5 N/cm, making gentle apical movements until resistance is encountered. Then, withdraw the file in circumferential brushing movements along the lateral walls.

• Remove the file and clean the flutes.

• Irrigate and confirm patency using K-file #10.

• Reintroduce EVO FLEX 20/04 as described previously; 2 to 3 repetitions are generally needed to reach the working length.

• Irrigate and confirm patency using K-file #10.

• Use EVO FLEX 30/04 file as described previously.

• Proceed with the final irrigation protocol and obturation.

Large canals

• Fill the canal with irrigant.

• If the working length can be reached with a K-file #30 without prior shaping.

• Use EVO FLEX 45/04 directly with the same inward and backward movement previously described.

• Proceed with the final irrigation protocol and obturation.

Size Options